Product Description

We specialize in this field more than 45years, with the high quality and pretty competitive price. Here are our main products:

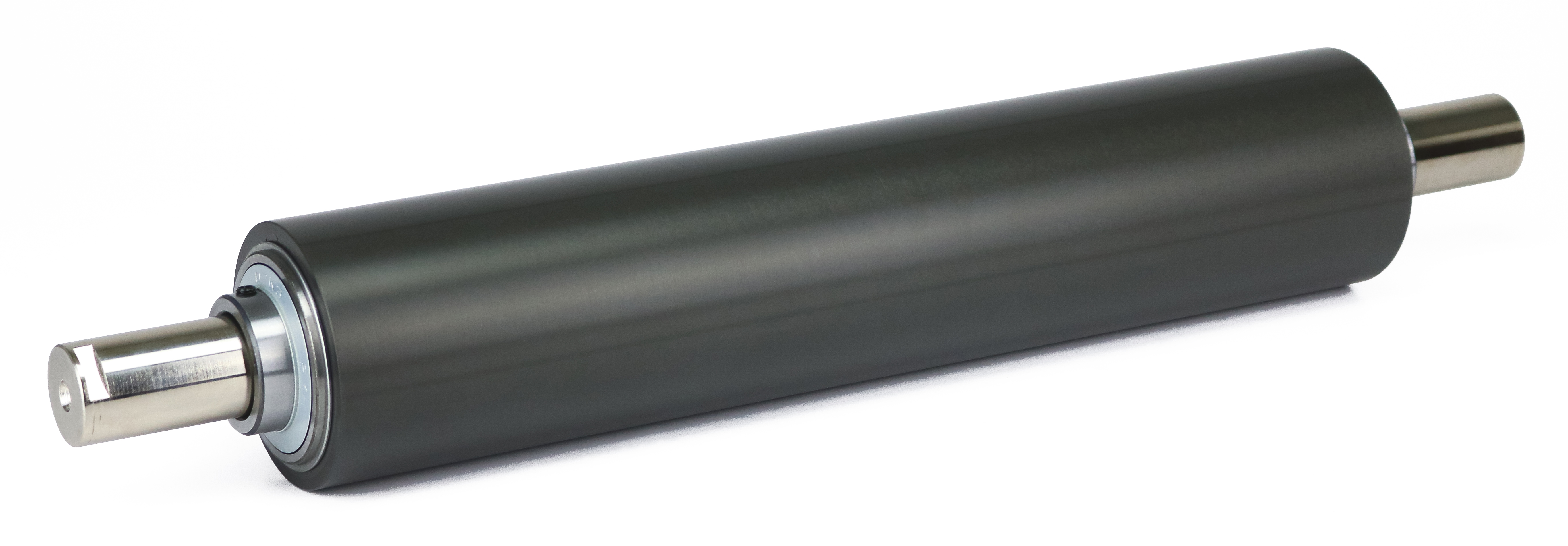

–Carrying Roller

–Return Roller

–Impact Roller

–Comb Roller

–Rubber sprial return roller

–Conveyor Roller set

–Conveyor Roller Frames

–Conveyor pulley

Materials can be used Steel, HDPE, etc.,standard can be GB, DIN, CEMA, etc, our rollers with

stable running, high quality bearing,accurate steel pipe and long lifespan.Also can produce according

to your drawing. Our products are sold to the world and receive a high reputation from our customers.

We will test every batch of cargo to make sure every piece rollers are qualified before delivering,

and supply you picture and professional inspect report. Hope to cooperate with you with our outsanding

service and assured products.

Steel Return Conveyor Roller/Heavy Duty Belt Conveyor Carrying Conveyor Roller/Mining Belt Conveyor Roller Idler

Our products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

|

SPECIFICATIONS |

|||

|

Diameter |

φ89, φ102, φ108, φ114, φ127, φ133, φ139, φ152, φ159, φ165, φ194 |

||

|

Length |

145mm-2800mm |

||

|

Tube |

Q235(GB), Q345(GB), welded with DIN2394 standed |

||

|

Shaft

|

A3 and 45# steel(GB) |

||

|

Bearing |

Single & Double Row Deep Groove Ball Bearing 2RS&ZZ with C3 clearance |

||

|

Bearing Housing/Seat |

Cold press working fit ISO M7 accuracy Deep Press steel with raw material fit DIN 1623-1624 standard |

||

|

Lubricating Oil |

Grade 2 or 3 long-lasting lithium greasae |

||

|

Welding |

Mixed gas shielded arc welding end |

||

|

Painting |

Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting |

||

| Diameter of Tube | Length of Tube | Bearing Type | Tube Wall Thickness | |

| mm | inch | mm | (mm) | |

| 63.5 | 2 1/2 | 150-3500 | 6204 | 3.0-3.75 |

| 76 | 3 | 150-3500 | 6204 6205 | 3.0-4.0 |

| 89 | 3 1/2 | 150-3500 | 6204 6205 | 3.0-4.0 |

| 102 | 4 | 150-3500 | 3.5-4.0 | |

| 108 | 4 1/4 | 150-3500 | 3.5-4.0 | |

| 114 | 4 1/2 | 150-3500 | 3.5-4.5 | |

| 127 | 5 | 150-3500 | 3.5-4.5 | |

| 133 | 5 1/4 | 150-3500 | 6306 | 3.5-4.5 |

| 140 | 5 1/2 | 150-3500 | 6306 | 3.5-4.5 |

| 152 | 6 | 150-3500 | 4.0-4.5 | |

| 159 | 6 1/4 | 150-3500 | 4.0-4.5 | |

| 165 | 6 1/2 | 150-3500 | 6308 | 4.5-6.0 |

| 177.8 | 7 | 150-3500 | 6309 | 4.5-6.0 |

| 190.5 | 7 1/2 | 150-3500 | 6309 | 4.5-6.0 |

| 194 | 7 5/8 | 150-3500 | 6310 | 4.5-6.0 |

| 219 | 8 5/8 | 150-3500 | 4.5-6.0 | |

Global Conveyor Supplies Company Limited

Belt conveyor idler Trough roller trough idler conveyor rollerRS water proof and dust proof heavy-duty roller/Idler–Return Roller/Idler/Roll, Carrier roll, trough roller/idler/roll

1.This RS series rollers belong to CHINAMFG high-end conveyor roller.

2. This return/carrier/trough roller has high precision structure, composing as many as 9 seal parts which ensure the roller good capability of water and dust resistance. With rubber or steel seals, multi-labyrinth seals.

3. The bearing housing and tube is full welded to ensure the well contact of the whole roller. Grease is permanent lubricant.

4. Roller surface could be painted any color as per customer request.

5. Material: normally Q235 tube (specially for conveyor roller), A3 cold-drawn shaft (Could be of very high precision to meed different customer requirement.)

6. Each roller would be through strict inspection and test to ensure every out coming roller are of true high quality.

Welcome to contact us at any time for conveyor roller/idler. We are professional and excellent in technology and service.

We know how to make our converyor roller to move your business!

It is common transportation equipment used in coal mines to connect downhole operations and on-ground production systems. In the course of use, it has many advantages, such as strong Transportation capacity, low power consumption, low work resistance, long service life, etc. Conveyor systems are quick and efficient transportation for a wide Variety of materials, which make them very popular in the material handling and packaging industries.

Sales form: factory direct sales

Dimensions: Φ63.5, Φ76, Φ89, Φ108, Φ114, Φ127, Φ133, Φ152, Φ159, Φ165, Φ194, Φ219 or custom size

Bearing brand: TNT, famous Chinese brand

Order quantity, price: negotiable

Product brand: GCS, RKM

Material: polyurethane, Carbon steel

Application: Conveyor roller industry

Product Type: Polyurethane Roller, Carbon Steel Roller, Ultra Polymer Roller, Stainless Steel Roller

About roller,we can make gravity conveyor roller,steel conveyor roller,driving roller,light middle duty conveyor roller,o-belt tapered sleeve roller,gravity tapered roller,polymer sprocket roller and so on.More details,please contact us.

Main Features

1) CHINAMFG design, suitable for heavy lifting.

2) The bearing housing and steel tube are assembled and welded with a concentric automatic.

3) Cutting of the steel tube and bearing is performed with the use of a digital auto device/machine/equipment..

4) The bearing end is constructed to ensure that the roller shaft and bearing can be firmly connected.

5) Fabrication of the roller is effected by an auto device and 100% tested for its concentricity.

6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA standard.

7) The casing is manufactured with highly composite, anti corrosive alloy.

8) The roller is lubricated and free from maintenance.

9) Woring life expectancy is up to 30,000 hours or more, depending on usage.

10)Vacuum sealed which has withstood anti water, salt, snuff, sandstone and dust proof experiments

Associated Products

Testing Machines

Certifications

Our Service

Our Company

Global Conveyor Supplies Co., Ltd.

Established in 1995; Land area = 20,000 m2; Staff= 120 persons.

Located in HangZhou, ZheJiang Province, next to HangZhou city.

GCS, RKM is a registered trademark in China.

GCS enjoys a renowned reputation and our products are marketed globally in South-East Asia, Middle East, Africa, Australia, Europe, Hong Kong and many other countries.

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant, Conveyor |

| Structure: | Ordinary Roller |

| Bearing Type: | Double Sealed Bearing |

| Type: | Grooved Conveyor Idler |

| Color: | Customized |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do electronic or computer-controlled components integrate with idler rollers in modern applications?

Electronic or computer-controlled components play a significant role in modern material handling applications, and they can integrate with idler rollers to enhance functionality, monitoring, and control. Here’s a detailed explanation of how electronic or computer-controlled components integrate with idler rollers in modern applications:

- 1. Sensor Integration:

Electronic sensors can be integrated with idler rollers to gather real-time data about their performance and the surrounding environment. For example, proximity sensors can be used to detect the presence or position of materials on the conveyor belt. These sensors can provide feedback to the control system, enabling automatic adjustments in the material handling process, such as activating diverters or adjusting conveyor speed based on the material’s position.

- 2. Load Monitoring:

Load cells or weight sensors can be utilized in combination with idler rollers to measure the weight or load of materials being conveyed. This information can be transmitted to a computer-controlled system for real-time monitoring and control of the material handling process. Load monitoring can help optimize material flow, prevent overloading, and ensure efficient operation of the conveyor system.

- 3. Condition Monitoring:

Idler rollers can be equipped with electronic monitoring devices to assess their condition and detect any abnormalities or signs of wear. Vibration sensors, temperature sensors, or acoustic sensors can be integrated to monitor roller performance and detect potential issues such as bearing failure, misalignment, or excessive wear. This data can be analyzed in real-time or transmitted to a central control system for condition-based maintenance, allowing for proactive repair or replacement of idler rollers before failures occur.

- 4. Automated Control and Optimization:

Computer-controlled systems can integrate with idler rollers to automate and optimize material handling processes. By analyzing data from sensors and other sources, the control system can make real-time decisions and adjustments to optimize conveyor speed, belt tension, and idler roller positioning. This automation improves efficiency, reduces human intervention, and enhances overall system performance.

- 5. Communication and Connectivity:

Electronic or computer-controlled components in idler rollers can be equipped with communication capabilities to connect with other devices or systems in the material handling environment. This allows for seamless integration with supervisory control systems, data logging systems, or enterprise resource planning (ERP) systems. The idler rollers can send data, receive instructions, and participate in a networked ecosystem for centralized control, monitoring, and reporting.

- 6. Predictive Analytics and Maintenance:

By combining electronic sensors, data analysis, and computer-controlled components, modern applications can employ predictive analytics to anticipate idler roller failures or maintenance needs. Advanced algorithms can analyze historical data, sensor inputs, and operational parameters to predict the remaining useful life of idler rollers. This enables proactive maintenance planning, reducing downtime, and optimizing maintenance schedules for improved overall system availability.

In summary, electronic or computer-controlled components integrate with idler rollers in modern applications to enhance functionality, monitoring, and control. Sensor integration, load monitoring, condition monitoring, automated control, communication and connectivity, and predictive maintenance are some of the ways these components work together to optimize material handling processes, improve efficiency, and increase the reliability of idler roller systems.

How does the design of idler rollers contribute to efficient and smooth material movement?

The design of idler rollers plays a crucial role in facilitating efficient and smooth material movement in conveyor systems. Various design features are incorporated to optimize the performance and functionality of idler rollers. Here are some ways in which the design of idler rollers contributes to efficient and smooth material movement:

- Roller Diameter and Length:

The diameter and length of idler rollers are carefully determined based on the specific application and load requirements. Larger roller diameters distribute the load over a larger surface area, reducing the pressure on the belt and minimizing belt deformation. Longer idler rollers provide more support along the conveyor belt, ensuring better weight distribution and reducing the risk of sagging or belt misalignment. The appropriate selection of roller diameter and length helps maintain optimal belt tension and prevents material spillage, contributing to smooth material movement.

- Roller Material and Construction:

The choice of materials and construction of idler rollers are essential for their performance and durability. Idler rollers are commonly made from materials such as steel, rubber, or high-strength composites. The material selection depends on factors such as load capacity, environmental conditions, and the type of material being conveyed. For example, steel rollers provide excellent strength and durability for heavy-duty applications, while rubber-coated rollers offer enhanced grip and reduced noise levels. The construction of idler rollers incorporates features like precision bearings, shafts, and seals to ensure smooth rotation and minimize friction, contributing to efficient material movement.

- Roller Configuration:

The configuration of idler rollers is optimized to support the conveyor belt and facilitate smooth material movement. Troughing idler rollers, with their concave shape, help contain the material being conveyed and prevent spillage off the sides of the belt. Impact idler rollers are designed to absorb the impact of heavy or sharp-edged materials, protecting the belt and reducing material degradation. Return idler rollers support the return side of the belt and assist in belt tracking, ensuring proper tension and alignment. Training idler rollers can be adjusted to apply lateral forces and guide the belt back to the center of the conveyor frame, minimizing belt misalignment. The appropriate configuration of idler rollers ensures proper belt support, alignment, and tracking, contributing to efficient and smooth material movement.

- Roller Surface and Coatings:

The surface of idler rollers is designed to minimize friction and optimize material movement. Idler rollers may have smooth or textured surfaces depending on the specific application requirements. Smooth surfaces reduce friction between the roller and the belt, reducing power requirements and energy consumption. Textured surfaces, such as diamond or spiral patterns, enhance grip and prevent material slippage on steep inclines or in wet conditions. Additionally, idler rollers can be coated with materials like polyurethane or rubber to further reduce friction, enhance belt grip, and provide additional protection to the belt surface. The surface design and coatings of idler rollers contribute to efficient and smooth material movement by reducing belt slippage, minimizing wear, and improving overall conveyor system performance.

In summary, the design of idler rollers is carefully engineered to optimize their performance and contribute to efficient and smooth material movement. Factors such as roller diameter and length, material selection, roller configuration, and surface design all play a role in ensuring proper belt support, alignment, and reduced friction. By providing adequate support, minimizing belt deformation, and reducing frictional resistance, well-designed idler rollers contribute to the overall efficiency, reliability, and longevity of conveyor systems in facilitating the movement of materials.

editor by CX 2023-11-27